Simucube has a reputation within the sim racing fraternity for products that last. And last. And last…

To that point, the Simucube 2 Ultimate wheel base, Simucube Throttle and Simucube ActivePedal all come with a five-year warranty. The company still provides software updates for the Simucube 1 wheel bases, such as recently providing iRacing 360Hz support, proving that there are enough customers out there still using a device that is up to eight years old.

That durable, reliable, reputation isn’t something that you can invent overnight, and it stems from the very beginning of product development.

The right mindset

According to the Simucube research and development team, it all starts with not just the right quality parts and testing regimes, but also a clear mindset and appropriate working environment.

“There are a lot of people at Simucube with a long history of creating very durable products,” explains the company’s Head of R&D, Vesa Saastamoinen.

“Firstly, we must take care of them and make sure our work environment is good, because the design work can be very demanding.

“We must make sure the team has enough resources to be able to create something totally new, because it’s like a black hole. You don’t really know anything when you are starting off, and in that kind of situation, you don’t have a time schedule either, so you can’t estimate anything.

“The end goal is something totally new on the market, and our ActivePedal is a very good example of that.”

According to the Finnish corporation, there is a clear department-wide mindset instilled into all research and development members that all products should be created with a long life in mind.

“To get everything to work and be long-lasting, you will need a peaceful work space so that you can focus on the design. So that is our main principle in the R&D department, that we guarantee that the team has the ability to focus on the work,” says Saastamoinen.

Entering what is termed a ‘flow-state’, analogous to when a sim racer is on track, completely at one with the car, at the peak of the performance. Take that feeling, but apply it to the Simucube creation team at their peak performance, inventing new technologies.

From prototype to production

Naturally, making sure the right ideas are formulated is key, but so is being able to scale those embryonic kernels of genius into a production-worthy product, according to Saastamoinen:

“When we are talking about innovative high-quality products and pushing the design to full-scale production, then this is the hardest part.

“It’s quite easy to do like five copies of a very high-quality level and get everything right. When you are building with your hands, you can check everything, and it’s perfect.

“But when you are talking about making 1,000 copies of that in serial production, with everything to the same quality level, that’s the difficult part.”

Moving from prototype to production involves selecting the right parts, which can strike the balance between not being “ridiculously expensive” but also long-lasting and durable. It must meet Simucube’s vision of a ‘forever product’.

“The real goal of our product development phase is to create a product that will not break down and does not have a limited lifetime,” continues Saastamoinen.

“To achieve that, in most cases, that means using industrial-grade parts like automotive or manufacturing-type elements, as they use very long-lasting components and materials.

“This is because when a factory is running, it needs to run for the next five decades, or something like that, without repairing. Of course, there is always maintenance, but the idea is that it lasts forever thanks to the industrial-grade components.”

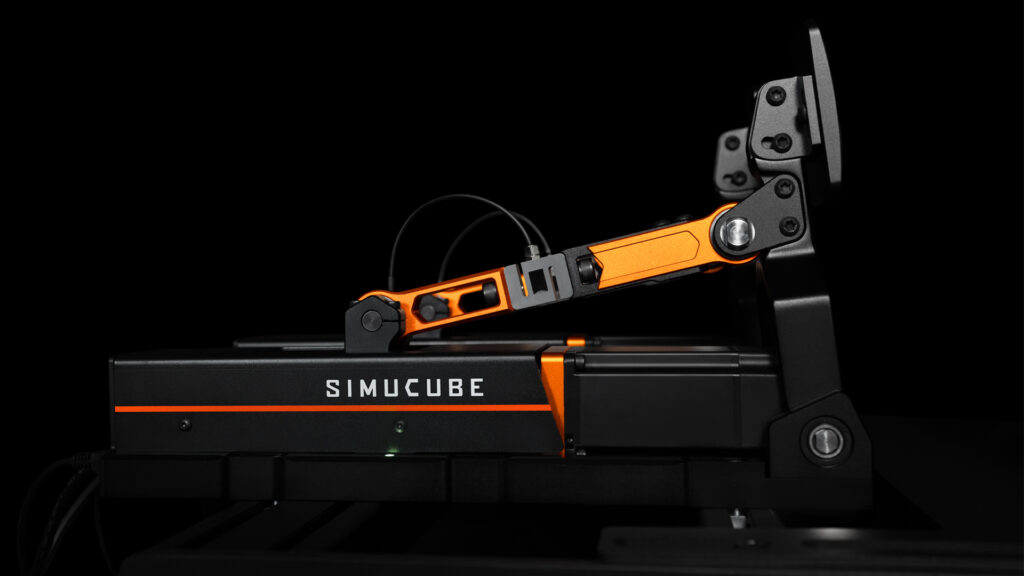

“We have chosen aluminium in many of our products as it’s a long-lasting material and then, when you don’t want to use it any more, it’s fully recyclable,” adds Project Engineer at Simucube, Markus Nuuja.

The ActivePedal’s industry-leading example

The combination of the right mindset, focus-encouraging working environment and industrial components is perhaps best typified in the aforementioned Simucube ActivePedal.

“If you take the Simcube ActivePedal, it took some time to create the first proof of concept and validate the idea,” expands Nuuja.

“We started with the Simucube 2 wheel base and how to use that technology to create a pedal, and the first versions didn’t work that well, of course. But after a while, it got better, and in the end, we got where we wanted, and the rest is history.

“We had the first ActivePedal, and now we can see, thanks to our technological leadership, that the whole field has pivoted because of us.”

But, according to the team, that hasn’t been the most challenging item to develop. Instead, they agree that it’s “probably our next product…”

Chat with the Community

Sign Up To CommentIt's completely Free